Maintenance Program Tab

The Maintenance Program tab allows the definition of well maintenance activities in two different ways: Well downtime models unscheduled, averaged decrease in well performance as a percentage of potential performance throughout the well's life; Well interventions, on the other hand, model individual operations which will stop production (or injection) for a specified length of time, with associated costs and rig usage.

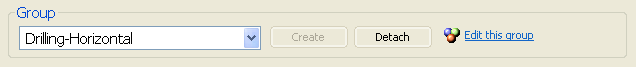

Group: Wells may be added to Well Groups using this pane, either by including them in an existing group (selected from the dropdown list on the left) or by creating it with the Create button. When a group is selected the data is no longer editable in this tab but can be accessed via the corresponding Wells Group node (use the  Edit this group link). Conversely, use the Detach button to remove the well from the group and edit its details in this tab.

Edit this group link). Conversely, use the Detach button to remove the well from the group and edit its details in this tab.

Operational Resource Requirements: Use this Resource Requirements Pane to define resource usage during the well lifecycle. Notice that usage will continue from the moment the well starts producing/injecting until it is abandoned even if production is temporarily halted by an intervention or a shut-in policy.

Well Downtime

Downtime: Enter downtime as a percentage of potential performance.

Well Interventions

Check the Define interventions box to create a maintenance program by defining scheduled interventions.

Choose Cost Category: Choose a category for operational, abandonment and maintenance (intervention) costs for this well (see Cost Categories).

Choose Cost Category: Choose a category for operational, abandonment and maintenance (intervention) costs for this well (see Cost Categories).

When Define interventions is selected, right-click the table area of use the  Add Intervention button to add a maintenance record. To schedule subsequent interventions, new rows can be added in the table. The following input is required in the table:

Add Intervention button to add a maintenance record. To schedule subsequent interventions, new rows can be added in the table. The following input is required in the table:

- Day Rate: Intervention cost per day.

- Fixed Cost: Fixed expenses per intervention.

Results Window this result will be included as Well Intervention under OpEx.

Results Window this result will be included as Well Intervention under OpEx.- Days: Duration of each intervention.

- Interval: Interval (in years) between the time of completion or last intervention and the start of this intervention. Only available if Automatic Scheduled is selected below.

- Rig: Select the rig that will perform each intervention. If you select none, the intervention will be executed exactly when scheduled. If you select a specific rig, the intervention will be subject to rig availability.

- Priority: Choose whether the selected intervention has higher or lower priority than drilling activities already queued by the rig performing the intervention.

Stop production while subject to intervention: If unchecked, well production will not be affected by any of its interventions. When checked, the well's potential production will be reported as zero.

Schedule automatically: If checked, interventions defined in the table will be automatically performed without the need to define separate Well Maintenance jobs. If unchecked, the interventions will not be performed if not included in a maintenance job defined separately in the schedule.

Cyclic - Restart program after last intervention: Restart at top record after completing the last one. Only available if Schedule automatically is selected. Interventions will thus keep being performed until the well's abandonment.

Workovers that do not impact the well's performance are best modeled as interventions rather than recompletions; see Adding completions.

Recompletions, Conversions and Workovers